Š°¡Š˜¡

YH 95234

VG95234 õñõýˋõ°¥ š¥š¿ÚŠ, YH-Bayonet šŠÎ˜šÎ š£ÊŠËÚ¯ š ŠŠÊ. šÇ š£ÊŠËÚ¯Š 5015š Šš˜š õý¯ÚˋŠ¯ˋšš bayonet Š¯ˋšš¥ŠÀ õ¯ŠÚš˜ õý¯Úˋ/ŠÑŠÎ˜õ¯ š§ŠŠÀ š šŠ š£ÊŠËÚ¯ š ŠŠÊ. šÏŠš šÚ š šýÇ š¿´Ú˜ŠÀŠÑÚ¯ Š°ÇÚ¡ŠË¥ Šˆˋš š¥ŠÀ ÚŠ õ°°š š˜šˋÚŠŠ¯ š ÚˋÚŠŠÀ šÊõ°Š š ښNJˋ¯, õý¯Úˋ/ŠÑŠÎ˜õ¯ š§ŠŠÀ šÊõ° ŠššçŠŠÊ. ÚÙõ°çõ¡¯ Š¯ õ篚ˋ š¯´Š, š š¯´, Š¯¯ŠÝš šËŠ¿ Š¯ š Š°ÇÚçš šËŠ¿ ŠÝš š˜šˋŠõ° ššçŠŠÊ.

šÈ¥Š˜¡ š Š°Ç (Ordering Information)

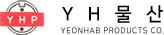

VG Nomenclature

- Series VG95234

- Shell Style

-

J1, J2, N1, N2, S1, U1, U2 - Wall Mounting Receptacle

F - Cable Connection Plug

A, B1, B2 - Box Mounting Receptacle

C1, C2 - Bulkhead Receptacle

D, G, H, L, M, R1 - Straight Plug

E, E1, K - Plug 90ô¯ - Shell Size

- 10SL, 14S, 16S, 16, 18, 20, 22, 24, 28, 32, 36

- Contact Arrangement

-

Refer to VG95234 specification

- Contact Style

-

P - Pin Contact

S - Socket Contact - Contact Type

-

Letter 1 indicates the electrical wire size.

- Alternate Insert Position

-

Refer to VG95234 specification.

- VG Accessories

-

VG95234 BOD - Dummy Receptacle

VG95234 DA - Gaskets, Front Mount

VG95234 DH - Gaskets, Rear Mount

VG95234 KR - Protecting Caps

VG95234 KB - Protecting Caps

VG95234 KK - Cable Caps

VG95234 KT - Bushing

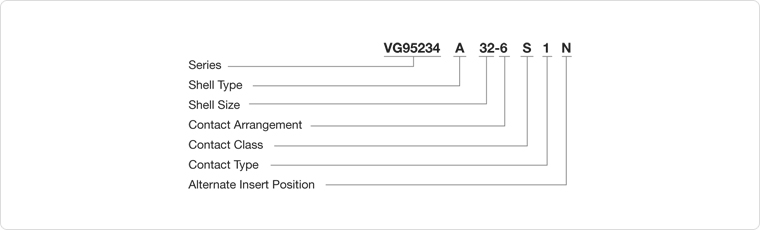

YEONHAB Nomenclature

- Shell type

-

YH3100 - Wall Mounting Receptacle

YH3101 - Cable Connection Plug

YH3102 - Box Mounting Receptacle

YH3106 - Plug, Straight

YTBF - Bulkhead Receptacle - Environmental rating

-

E - appropriately uses clamp and bushings in flexible rubber insulator and end bell.

- Shell Size

- 10SL, 14S, 16S, 16, 18, 20, 22, 24, 28, 32, 36

- Contact Arrangement

-

Refer to the VG95234 specification and MIL-STD-1651.

- Contact Style

-

P - Pin Contact

S - Socket Contact - Alternate Insert Position

-

Refer to the VG95234 specification and MIL-STD-1651.

- Connector Coupling Method

-

Bayonet Coupling

- Measurement Information

-

01-Metric clamping contact

02-Uses heat shrink boots in adaptor. AWG clamping contact

03-Uses heat shrink boots in adaptor. Metric clamping contact

04-Rear Mount. Screw-type hole flange. Metric clamping contact

05-Rear Mount. Screw-type hole flange. Soldering type contact (YH3100, YH3102, YTBF applied) 06-Heat shrink boot adaptor. Screw-type hole flange. Soldering type contact

08-90ô¯ end bell. Screw-type hole flange (YH3100 applied)

09-90ô¯ end bell. Through-hole flange (YH3100 applied)

13 - shield version. Soldering type contact

14 - shied version. Metric clamping contact.

15 - shield version. AWG clamping contact.

32 - end bell structure for shield system cable. MTV6145-005.

109-F80. Rear Amount. Screw-type flange(YH3102 applied)

111-Rear amount. screw-type flange(YH3102 applied). Soldering type contact.

F80-AWG clamping contact.

A232 - Zinc cobalt plating(black)

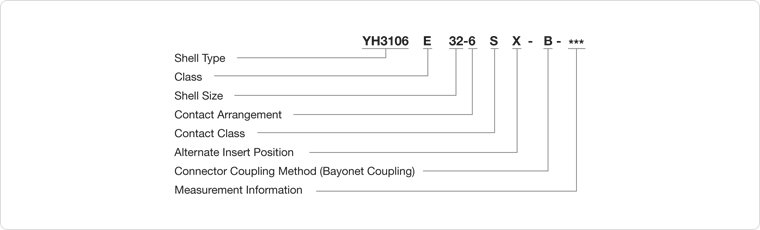

YEONHAB Nomenclature

- Product Type

-

YHB-General connector

YHBG-EMI Ground Finger type connector - Material Type

-

Blank - Standard(CR) insulator

V - Silicon(SR) insulator - Shell Size

-

01 - In-Line Receptacle

02/00 - Front Panel Mount Receptacle

03/030 - Rear Panel Mount Receptacle

06 - Straight Plug

07 - Single Hole Mount Jamnut Receptacle, No Rear Thread

070 - Single Hole Mount Jamnut Receptacle, With Rear Thread

08 - 90ô¯Plug - Shell Size

-

10SL, 14S, 16S, 16, 18, 20, 22, 24, 28, 32, 36

- Contact Arrangement

-

Refer to the VG95234 specification and MIL-STD-1651.

- Alternate Insert Position

-

Refer to the VG95234 specification and MIL-STD-1651.

- Contact Type

-

F80-AWG clamping contact

CR-Metric clamping contact

Blank - soldering contact - Environmental Rating

-

It is based on the accessories and backshell that seal according to each rating.

G - heat shrink boots are used for end bell accessories. includes grommet and bushing. (applicable to 01,00,030, 06)

AG - excludes grommet and bushing from G rating

R - other accessories are used for end bell accessories. includes grommet and bushing. (08-90 end bell)

SB - EMI blade and heat shrink boots used. includes grommet and bushing.

SBT - EMI blade, heat shrink ring and heat shrink boots used. includes grommet and bushing.

F - includes cable clamp and rubber bushing.

AF- excludes grommet and bushing from F rating

FP - the panel mounting hole is a through-hole type

RG - EMI coil ground finger tyle (applicable to 07, 070)

- Contact class

-

P - Pin Contact

S - Socket Contact

õ¡¯š š š Š°Ç (Technical Data)

Electrical Information

Electrical Information (20 ã)| Contact Rating | Max. Current | |

|---|---|---|

| Metric | AWG | A |

| 10 | - | 8 |

| 15/15S | 16/16S | 22 |

| 25 | 12 | 41 |

| 60/100 | 8 | 74 |

| 160 | 4 | 135 |

| 500 | 0 | 245 |

Contact Resistance

VG95319 Part 2š šÚŠýÚ¡ 5.12š VG95210 Part 32š šÚšÀ¯õÝÇ Bš š¥š¿Ú õý.ÚšÊ(CR) š š¯šýÇ > 1 000 Möˋ

šÊŠÎ˜š§(SR) š š¯šýÇ > 5 000 Möˋ

Required to meet the testing no. 5.12 in Part 2 of VG95319

and testing condition B in Part 32 of VG95210.

Standard(CR) insulator > 1 000 Möˋ

Silicon(SR) insulator > 5 000 Möˋ

Contact Resistance (Milivolt testing)

| Voltage testing per service rating | |

|---|---|

| Service Rating | Testing Voltage (V rms) |

| Instruments | 1 050 |

| A | 1 600 |

| B | 4 000 |

| D | 2 500 |

| E | 3 000 |

Air and Creepage Paths(Min.) (UNIT: mm)

| Voltage Rating | Instr. | A | D | E |

|---|---|---|---|---|

| Air and Creepage Paths | 0.70 | 1.10 | 2.80 | 4.80 |

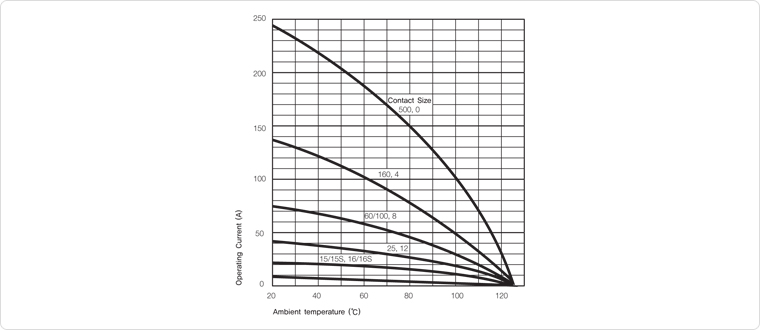

Current Rating (according to ambient temperature)

of VG95234 and Part 37 of VG95210.

It represents the actually measured point.

| Contact Rating | Max. Current | |

|---|---|---|

| Metric | AWG | Möˋ |

| 10 | - | 12 |

| 15S/15 | 16/16S | 6 |

| 25 | 12 | 3 |

| 60/100 | 8 | 1 |

| 160 | 4 | 0.5 |

| 500 | 0 | 0.2 |

Mechanical characteristics

Ambient temperature| Material | Temperature range |

|---|---|

| Standard(CR) insulator | -55 ã ~ 125 ã |

| Silicon(SR) insulator | -30 ã ~ 200 ã |

| Vibration testing | 200 дšš 10 Ð ~ 2 000 Ð |

| Coupling testing | Min. 500 times |

Contact Separating Force

| Contact Size | Separating Force(Min) | ||

|---|---|---|---|

| Metric | AWG | N | Gauge |

| 10 | - | 0.30 | G 0.99 |

| 15S/15 | 16S/16 | 1.00 | G 1.56 |

| 25 | 12 | 1.50 | G 2.36 |

| 60/100 | 8 | 3.00 | G 3.58 |

| 160 | 4 | 4.00 | G 5.69 |

| 500 | 0 | 8.50 | G 9.04 |

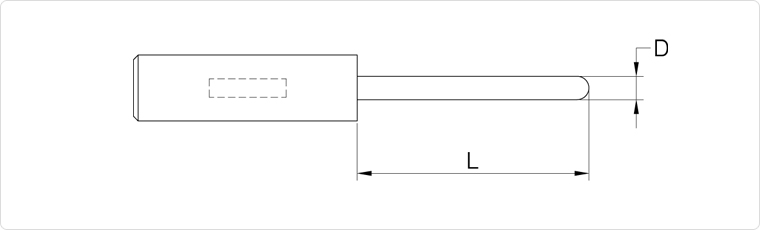

Gauge (VG95234, Part 1)

| Gauge | D +0.01 -0.00 |

L +0.00 -1.00 |

|---|---|---|

| G 0.99 | 0.99 | 7.00 |

| G 1.56 | 1.56 | 9.00 |

| G 2.36 | 2.36 | 12.00 |

| G 3.58 | 3.58 | 13.00 |

| G 5.69 | 5.69 | 13.00 |

| G 9.04 | 9.04 | 13.00 |

Coupling Torque

| Shell Size | Approved Coupling Torque | |

|---|---|---|

| Locking and unlocking Nm Max. |

unlocking Nm Min |

|

| 10SL | 1.70 | 0.15 |

| 14S | 3.60 | 0.35 |

| 16S/16 | 5.50 | 0.46 |

| 18 | 8.00 | 0.58 |

| 20 | 9.00 | 0.70 |

| 22 | 11.00 | 0.80 |

| 24 | 14.00 | 0.80 |

| 28 | 17.00 | 0.92 |

| 32 | 19.00 | 1.03 |

| 36 | 23.00 | 1.03 |

Contact Retention Force

| Contact Size | Testing power | |

|---|---|---|

| Metric | AWG | N |

| 10 | - | 30 |

| 15S/15 | 16S/16 | 35 |

| 25 | 12 | 55 |

| 60/100 | 8 | 80 |

| 160 | 4 | 90 |

| 500 | 0 | 95 |

Testing power direction = locking direction.

Material and protection coating

| Body | aluminum alloy |

|---|---|

| Standard protection coating | cadmium plating(viridescent color) on top |

| Substitute protection coating | Zinc cobalt plating(black) |

| Insulator and grommet | Chloroprene Rubber(standard) Slicone Rubber(for high temperature) |

| Contact | Copper alloy |

| Protection coating | Hard silver plating |

š š¯šýÇ (Insulator)

| NBR(Nitrile Butadiene Rubber) | CR(Chloprene Rubber) | |

|---|---|---|

| šËš | ŠÇš šÝšÇ š¯šÚ´(õý§š , ÚŠ¯š ) | ŠÇÚšÝ,ŠÇš§ÚšÝ,ŠÇš šÝ,Šš¯šÝ, šÊšÀÇšÝ, ŠÇšÇšÝ, Š ¡ÚšÝšÇ š¯šÚ´ |

| ŠÇŠÏŠˆ´šÝ,ŠÇššÝ, ŠÇŠ ¡ÚšÝšÇ š¯šÚ´ | õ¯šÊ Ú˜õ°¥šÝšÇ š š | |

| š š¯ˋŠ ËšÇ š¯šÚ´ | ||

| õçÇõ°ÀښǚÝ,ŠÇŠÏŠˆ´šÝšÇ š¯šÚ´ | ||

| ŠÇšÇšÝ 150 ãõ¿šÏ š˜šˋ õ¯ŠËÚ´ | ||

| õ¯õýˋ | ŠÛš | Šš |